Embarking on a quarry business venture requires thorough planning, understanding of the market demand, securing the right location, compliance with legal requirements, and assembling a skilled team. This guide provides a step-by-step approach to setting up a successful quarry business.

1. Market Research

Understand Demand

Conduct research to identify the demand for quarry products in your target market. Analyze construction trends and industries reliant on your potential offerings.

Analyze Competitors

Study existing quarry businesses to understand their strengths, weaknesses, pricing, and product offerings.

2. Business Planning

Business Plan Development

Develop a comprehensive business plan detailing your strategy, financial projections, marketing plans, and growth objectives.

Legal Structure

Select and register the legal structure of your business, such as a sole proprietorship, partnership, or corporation.

3. Licensing and Permits

Navigate through the local, state, and federal regulations to obtain necessary permits and licenses, ensuring compliance with environmental, safety, and zoning laws.

4. Site Selection and Development

Choose a site with accessible reserves and consider factors like transport links and water supply. Prepare the site according to your project plans, including clearing vegetation and arranging for water drainage.

5. Equipment and Staffing

Acquiring the right equipment and assembling a skilled workforce are crucial steps in establishing a successful quarry operation.

Equipment Needs

- Excavators and Loaders: For digging and moving materials.

- Drilling Equipment: To drill holes for explosives used in blasting rock.

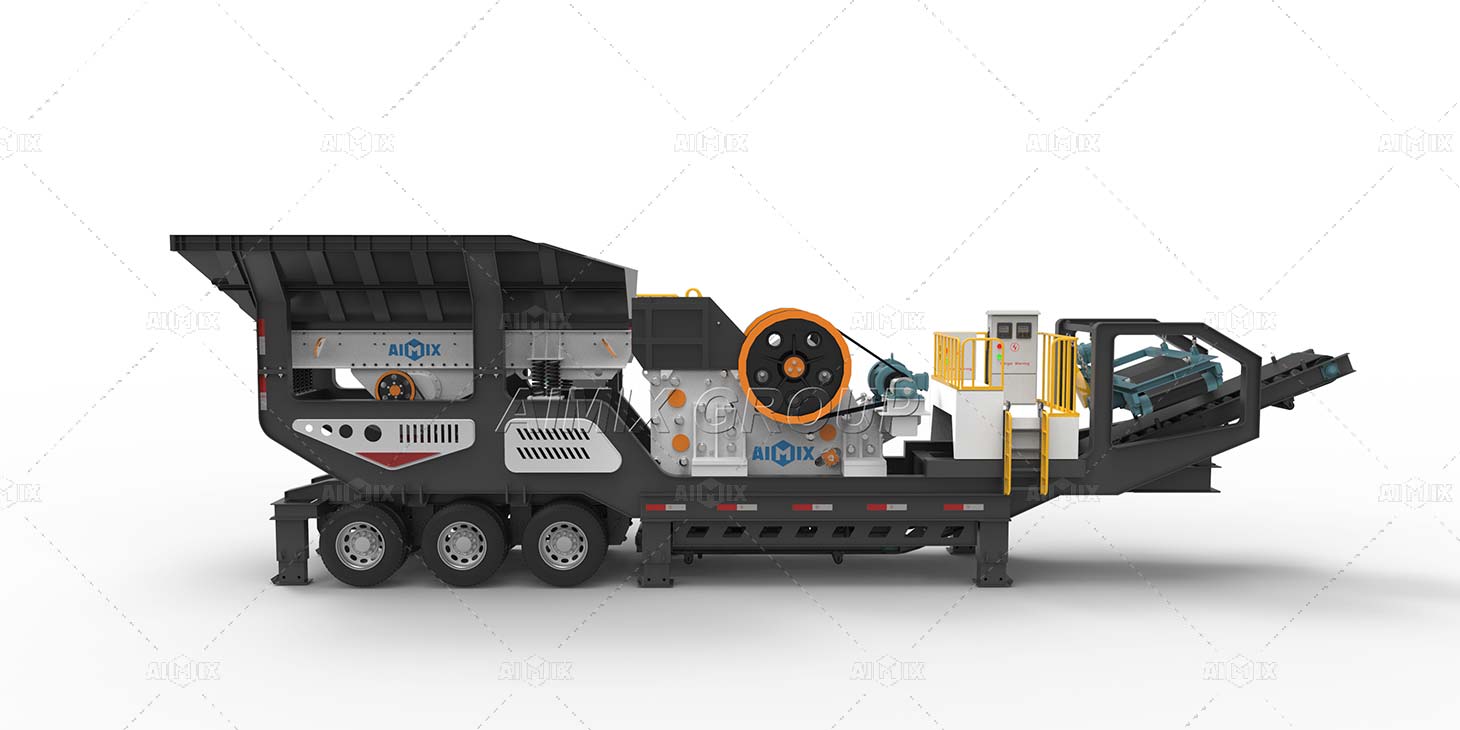

- Crushing and Screening Equipment: To break down rocks into usable sizes and separate them by size.

- Conveyance Equipment: Conveyor belts for efficient material transport.

- Dump Trucks: Essential for transporting material within and outside of the quarry.

- Safety and Maintenance Equipment: To ensure workplace safety and maintain other machinery.

Staffing Requirements

- Site Managers/Quarry Managers: Oversee daily operations and safety protocols.

- Mining Engineers/Geologists: Plan extraction processes and assess the quarry’s reserve quality.

- Equipment Operators: Operate the heavy machinery needed for quarry operations.

- Maintenance Technicians: Keep all equipment in working order to reduce downtime.

- Health and Safety Officers: Develop and enforce safety standards.

- Administrative Staff: Manage day-to-day administrative tasks.

6. Operation Launch

Establish safety protocols and begin operations, closely monitoring activities for efficiency and legal compliance.

7. Marketing and Sales

Build relationships with potential customers, develop a marketing strategy that highlights the quality of your products, and utilize various sales channels to reach your target market.

8. Continuous Improvement

Regularly evaluate your business performance, adapt to industry trends, and seek ways to improve productivity and reduce costs.

Choosing the right crusher for quarrying is critical to the success of your operation, impacting both efficiency and profitability. The selection depends on several factors including the type of rock, size of the material, desired output, and overall quarrying objectives. Here’s how you can make an informed decision:

How To Choose A Right Crusher For Quarrying

1. Understand Your Material

Type of Rock: Different crushers are optimized for different rock types. Hard rocks like granite might require a jaw crusher or a cone crusher, while softer rocks could be suitable for impact crushers.

Abrasion Characteristics: Highly abrasive materials can wear down certain types of crushers faster, affecting durability and maintenance costs.

Material Size: The size of the raw material directly influences the type of crusher you need. Large blocks of rock might necessitate a primary crusher, such as a jaw crusher, before moving to secondary crushing.

2. Desired Output

Size Specifications: Consider the size to which you need to break down the material. For fine materials, you might need a cone or impact crusher that allows for size control.

Production Capacity: Your desired production capacity – the amount of material processed per hour – will influence the size and type of crusher. Higher capacities typically require larger crushers with higher power ratings.

3. Mobility Needs

Stationary vs. Mobile: Determine if your operations would benefit from mobile crusher plants that can be moved and set up quickly or if a stationary setup is more appropriate for your long-term goals.

4. Consider Processing Stages

Single-stage vs. Multi-stage: Some operations might require multiple crushers to refine the material to the desired specifications. Assess whether you need a primary crusher for large material breakdown, followed by secondary and tertiary crushers for finer reduction and shaping.

5. Evaluate Operational Costs

Initial Investment: Higher capacity and more technologically advanced crushers tend to be more expensive upfront.

Maintenance and Wear Parts: Consider the ease of maintenance and the cost of wear parts. Certain crushers have higher wear rates or more complex maintenance procedures, impacting long-term operational costs.

Energy Consumption: Crushers vary in their energy efficiency. Operating costs can be significantly affected by the energy consumption of the machinery.

6. Consult with Manufacturers

Engage with manufacturers or suppliers who have extensive knowledge of various types of crushers. They can offer insights into the most suitable options based on your specific requirements.

7. Test Material

If possible, test your material with different types of crushers to see which one provides the best result. Some suppliers offer this as a service.

Starting a quarry business is a significant undertaking that requires careful planning and execution. By following these detailed steps, you can establish a profitable and sustainable operation that meets the demands of your target market while complying with all regulatory standards. Learn more about is quarrying mining profitable here.